Gravel, grit and stones are frequently found lying on roads and streets. If these are thrown into the air at high speed, they can strike vehicles and damage their paintwork. If holes or cracks are formed in the paint or if it flakes off, the paint is not able to protect the bodywork or rail vehicle as well against corrosion.

Automobile manufacturers therefore attempt to apply paint coats on the exterior of the bodywork that are resistant to such stone impacts. The extent to which a coating is resistant to numerous small particles can be simulated in stone impact tests. In this test the extent of the damage is dependent not only on the quality of the coating, but also on the strength of the compressed air, the mass of the particles and the duration of firing.

A standardised test procedure is required in order to render the results of such tests comparable. The International Organization for Standardization (ISO) has specified such regulations in its ISO 20567 standard. This standard consists of two parts. The multiple impact test is described in the first part. In this test small, sharp-edged objects are fired in quick succession at a coated steel test sheet, using compressed air. The German version of the standard is “Coating substances – Examination of the stone impact resistance of coatings – Part 1: Multiple impact testing”.

A number of details of the multiple impact test of ISO standard 20567:

- The test sheets are 200 mm long, 100 mm wide and 07 to 1.0 mm thick. The coating or multi-coat paint system that is to be tested is applied to the steel sheet.

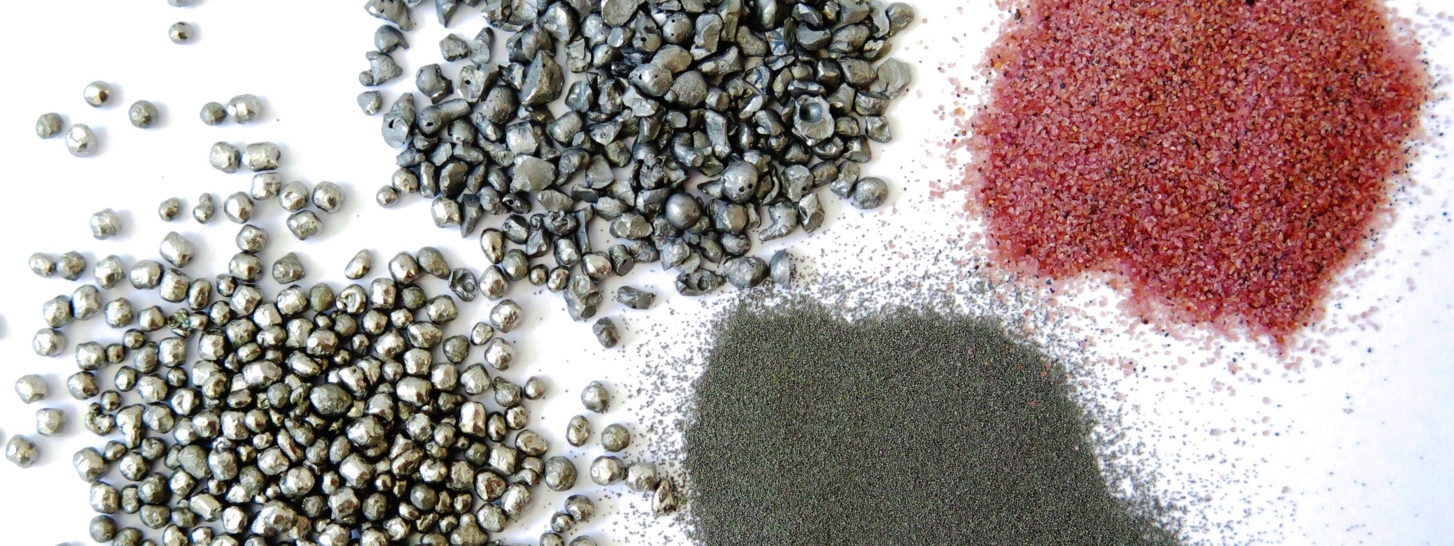

- The projectile material is a cast granulate with a grain size of 4 to 5 mm.

- Around 500 g of hard granulate is used in each shot.

- A coated sheet is bombarded with a load of granulate for a period of ten seconds, using compressed air. The angle of impact is 54°. The pressure is 100 or 200 kPa. This bombardment may be repeated once.

- Prior to evaluation a 25mm wide and 120 to 150 mm long section of adhesive tape is applied to the test sheet and abruptly removed again. This removes any loose material hanging from the sheet. The adhesive tape has an adhesive force of 6 to 10 N/25 mm.

Experts assess the degree of damage visually. This is achieved by comparing the test results with images from standard ISO 20567-1 and assigning them a co-efficient from 0.5 to 5. If less than 0.2 % of the surface is damaged, a co-efficient of 0.5 is awarded. This corresponds to very good resistance to repeated stone impact. If more than 81.3 % of the surface is damaged, this corresponds to the co-efficient of 5 and is very poor resistance to impact. This assessment can also be undertaken using digital image processing.

In practice, co-efficients of less or equal to 2 are accepted.

Two notes:

Car manufacturers such as Daimler, Ford, Renault and the PSA Group have developed their own stone impact tests, as has the German Association of the Automotive Industry (VDA). These are essentially similar to the multiple impact tests of ISO standard 20567.

In the second part of the ISO 20567standard a procedure is described with the aim of testing how a coating resists the one-off impact of a wedge-shaped impactor.

Belgium nederlands

Belgium nederlands Belgium français

Belgium français Canada english

Canada english Canada français

Canada français China chinese

China chinese Czech Republic čeština

Czech Republic čeština Deutschland deutsch

Deutschland deutsch France français

France français Hungary magyar

Hungary magyar International english

International english Italy italiano

Italy italiano Netherlands nederlands

Netherlands nederlands Poland polski

Poland polski Russia русский

Russia русский Slovakia slovenčina

Slovakia slovenčina Switzerland français

Switzerland français Switzerland deutsch

Switzerland deutsch Turkey Türkçe

Turkey Türkçe USA english

USA english